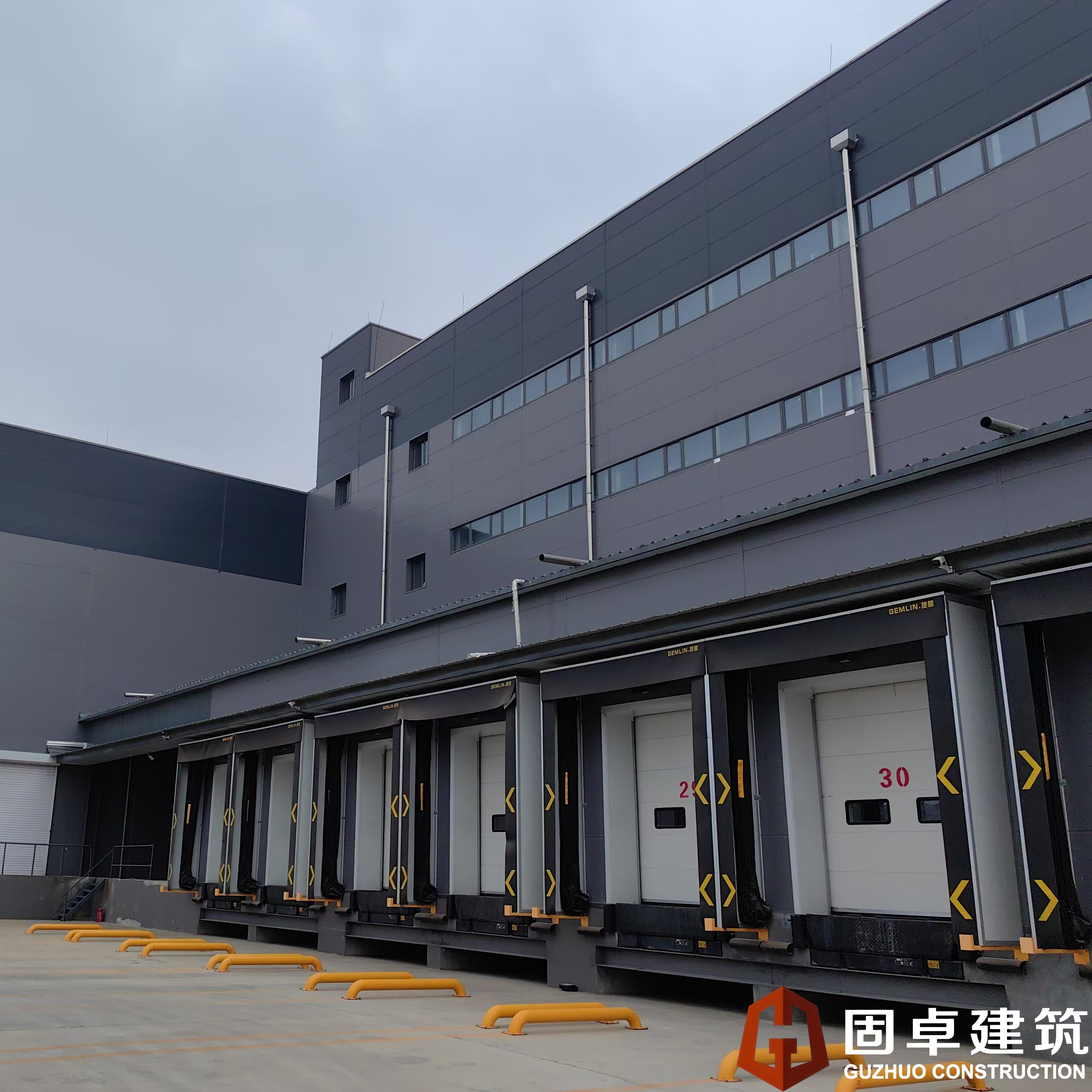

GFS Jingbin Cold Storage

Project Location Advantages:

Situated in Jingbin Industrial Park, Wuqing District, Tianjin, this project occupies the core of the Beijing-Tianjin-Hebei "Golden Triangle," serving as a critical bridge connecting Beijing and Tianjin. It borders Hebei’s Langfang to the west and Beijing to the north with seamless integration, offering outstanding locational advantages and unparalleled transportation accessibility.

Project Scale:

The operational 1#, 2#, and 3# cold storage facilities consist of low-temperature sorting workshops and supporting cold storage,with a 30-meter-wide turnaround area capable of accommodating large refrigerated trucks.

- 1# & 2# Cold Storage: Single-story, internally insulated prefabricated steel structure cold storage facilities with a total area of ~6,000㎡ and a chilled space of ~5,000㎡. They feature a 10.5-meter clear height, 8m×20m column spacing, and support dual storage configurations:

- 5-layer double-deep racks (pallet size: 1.2m×1.0m) with ~15,600 pallet positions.

- Shuttle racking system with ~25,000 pallet positions.

- Designed for 5 tons/m² uniform load capacity.

- 3# Cold Storage: A three-story civil-construction cold storage:

- First Floor: 9-meter clear height, 7.8m×7.6m column spacing, 4-layer double-deep racks (~4,524 pallet positions).

- Second & Third Floors: 4.5-meter clear height, bulk storage for warehousing/reserve-type goods (~6,490 pallet positions).

- Equipped with two 5T freight elevators for vertical transportation.

Project Construction Standards:

Refrigeration System:

- Uses eco-friendly R507 refrigerant, imported Sagawa screw compressors, flooded-type air coolers, and Danfoss valves.

- PLC automated control optimizes compressor/condenser/air cooler/valve operations based on set storage temperature for high energy efficiency.

Insulation:

- 1# & 2#: 200mm B1-rated PIR sandwich panels (walls), Beipeng XPS boards (500kPa) for flooring, and 5cm rock wool exterior cladding to achieve ≤0.5 kWh/day energy consumption.

- 3#: 200mm B1-rated sprayed insulation.

Roof & Flooring Systems:

- Roofs: "Sika PVC + rock wool + vapor barrier" single-ply waterproofing (steel structure for 1#/2#, civil construction for 3#).

- Flooring: 4mm Sikafloor 24N PurCem polyurethane mortar (cold storage-specific), ensuring integrity at -25℃.

- Delivered by Beijing Guzhuo Construction Engineering Co., Ltd., meeting international quality benchmarks.

Flexibility: 5 tons/m² load capacity supports both double-deep and shuttle racking for operational versatility.

Facilities: External sockets for refrigerated trucks and EV charging stations in the turnaround area.

Previous Page

Next Page

Previous Page

Next Page