Design and Node Technology of TPO Single-Layer Roofing System at APP Rudong Production Base

Abstract: The papermaking workshop, characterized by high humidity and temperature, requires exceptional performance from the building envelope system, particularly in terms of anti-corrosion, condensation prevention, and waterproofing for roof surfaces. This paper details the application of TPO single-layer waterproof roof systems at the Jinguang Rudong Household Paper Industrial Base project, providing a comprehensive analysis of system design and detailed node treatment for such industrial facility roofs.

Key words: TPO waterproof membrane; single layer roof system; paper making workshop; PIR insulation board

1. Engineering Background

Sinar Mas Group's Rudong Production Base stands as the world's largest single-site production facility for household paper products. Spanning 8,500 mu (approximately 1,280 hectares) with a total investment of 45 billion yuan, this three-phase project features an initial phase exceeding 10 billion yuan. The current phase will establish seven production lines, each equipped with four paper machines. Upon full completion, the base is projected to achieve an annual output capacity of 780,000 tons and generate over 10 billion yuan in annual revenue. As one of Nantong's most ambitious modern industrial projects, it utilizes imported wood pulp from Jinguang APP Group's facilities. For the first time, the base adopts an "Industry 4.0 + AI" production philosophy, creating a world-class eco-friendly industrial park that integrates advanced manufacturing, circular economy, and technological innovation. This green, energy-efficient hub serves as both a cutting-edge technology base and a premium household paper production center.

The production workshop is divided into two zones: the wet zone and the dry zone. The wet zone maintains a high-temperature, high-humidity environment where indoor temperatures exceed outdoor levels during winter. High-temperature water vapor interacts with roof steel plates, causing condensation formation. Additionally, some moisture penetrates through bolt holes and panel joints, leading to screw oxidation corrosion and insulation failure. Given the project's coastal location with strong wind pressure, both the owner and design team prioritized the waterproofing and insulation system. After extensive research and rigorous selection, they ultimately adopted a TPO single-layer roof system using PIR insulation boards for the papermaking workshop and post-processing workshop.

2. System design and material selection

2.1 System structure design

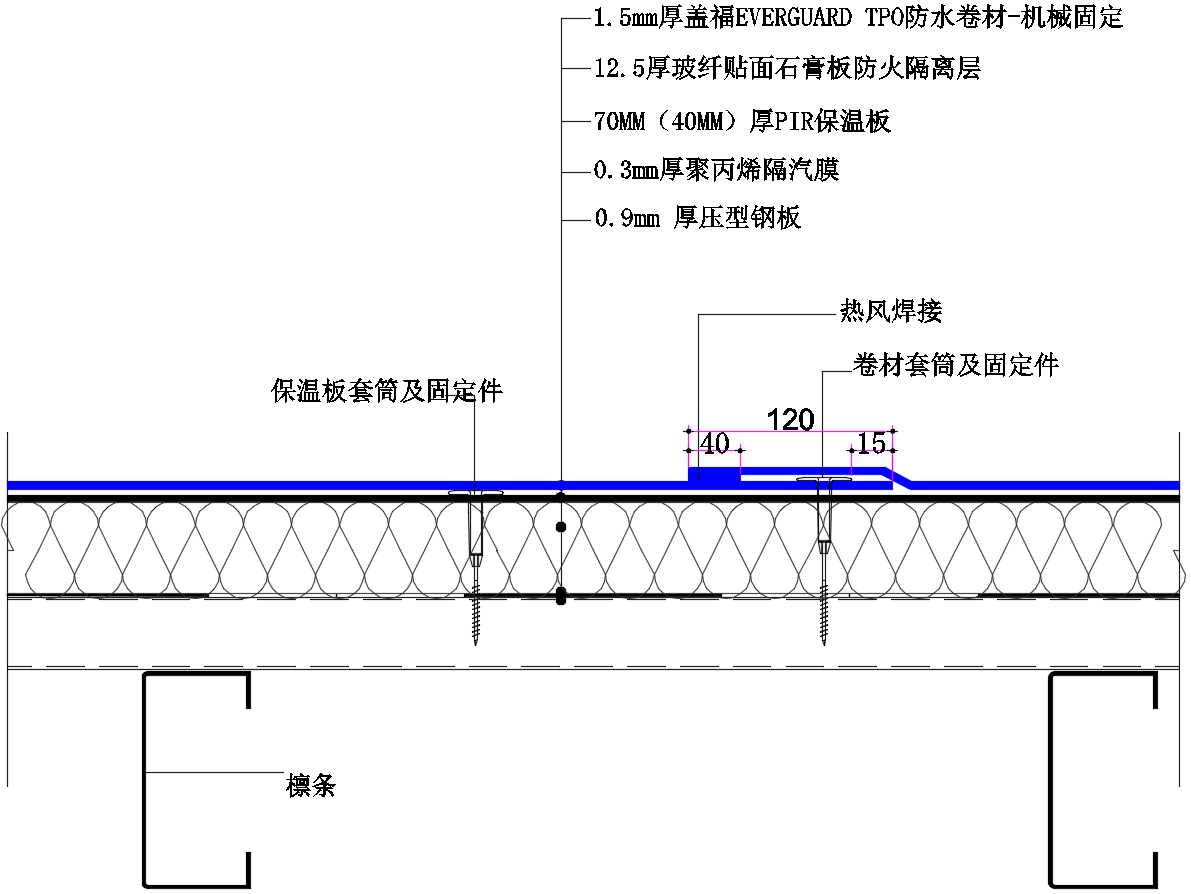

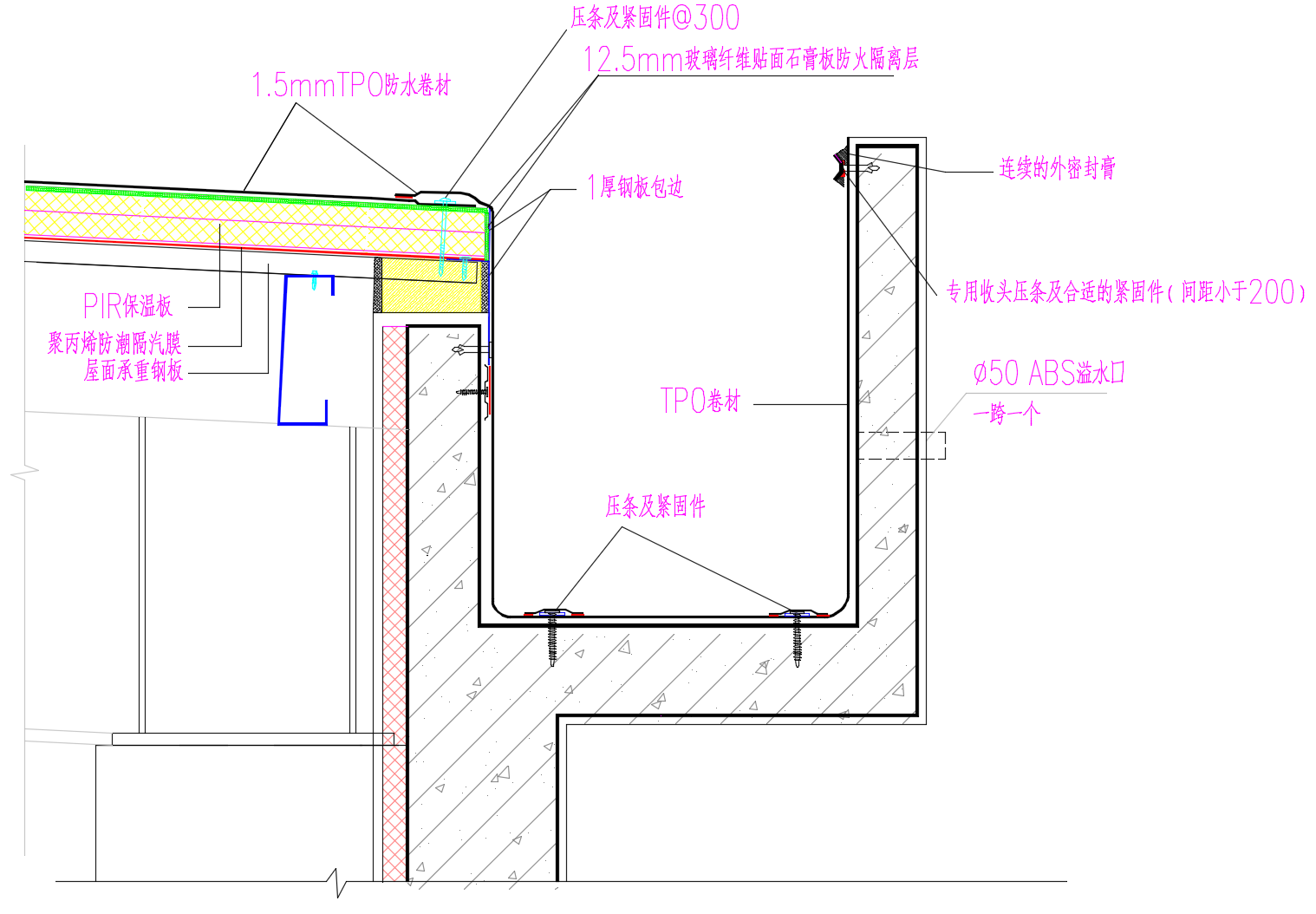

The project employs a TPO single-layer roof system for waterproofing and insulation. The waterproof layer utilizes 1.5mm-thick GAF polyester fiber-reinforced EVERGUARD TPO membrane. In the papermaking workshop (wet zone), TPO is bonded to the stainless steel roof panel base using "304 stainless steel nails with plastic sleeves". The dry zone roof is secured with specialized fasteners. The insulation layer consists of PIR board, topped with 12.5mm thick fiberglass-faced gypsum board as a fire-resistant barrier, and vapor barrier layer made of 0.3mm polypropylene film. The basic structural hierarchy of the roof is shown in Figure 1.

Figure 1 roof basic structure hierarchy diagram

Given the project's coastal location, frequent summer typhoons and other extreme weather conditions result in significant wind loads. By strictly adhering to national standards and design specifications for wind pressure parameters, combined with precise calculations of the roof structure, we have obtained comprehensive and accurate wind load data for the roof. This provides technical guidance for the installation of TPO membrane materials and fasteners.

2.2 Characteristics of corrosion and condensation of roof system

The waterproofing system's primary material is the imported American-made GAF polyester fiber reinforced TPO membrane. This premium TPO membrane boasts an 8,000-hour weather resistance test and has received FM-certified wind resistance and fire resistance ratings. The white TPO membrane enhances energy efficiency through its high reflectivity. The 3-meter wide roll significantly reduces overlap risks and minimizes leakage hazards. Its exceptional weldability accommodates complex roof node configurations, ensuring durable bonding even after prolonged use. Regular cleaning of the membrane surface maintains secure welding connections, facilitating maintenance operations.

Figure 2. Laying and welding of GAF TPO membrane

The PIR insulation panels used in this roof system are made from closed-cell polyisocyanurate foam material with a double-layer glass fiber reinforced surface. With a thermal conductivity coefficient (R value) of ≤0.023 W/(m·K), these panels outperform traditional rock wool insulation boards commonly used in flexible roofing systems in thermal insulation, moisture resistance, and compressive strength. Their lightweight design, easy installation, and long service life effectively eliminate the risk of condensation caused by moisture damage to rock wool insulation. All PIR panels in this project were manufactured using proprietary materials supplied by Dow Chemical Company (VORATHERM CN 831 polyol compound & VORACOR CE 181 isocyanate), ensuring high-performance stability and durability that meet the long-term requirements for single-layer roofing. PIR insulation panels are among the most widely used building products in North America.

Figure 3 Construction of PIR insulation board, polypropylene vapor barrier film and fireproof board

The roof surface utilizes polypropylene vapor barrier film with superior air-tightness and water resistance. Compared to conventional PE vapor barriers, it demonstrates enhanced mechanical properties and puncture resistance. When continuously installed beneath the insulation layer, this membrane effectively prevents indoor heat and moisture from migrating upward into the insulation system. It significantly reduces condensation formation in roof structures while resisting internal wind pressure and minimizing overall wind load. At parapet wall positions and all exposed component interfaces, complete sealing is achieved using butyl rubber tape, effectively blocking thermal air convection.

To meet fire safety requirements, the roof employs 12.5mm Taishan glass fiber cloth-faced gypsum board as a fire-resistant isolation layer. This product features reinforced glass fiber layers on both sides with gypsum core material inside, delivering superior fire resistance and wind resistance. Its unique structural design enhances the floor slab's cross-sectional span (slab opening width) while strengthening overall stability. With A1 fire rating certification, the gypsum board core demonstrates exceptional water resistance, fire endurance, and weather resistance. It also offers antibacterial/mold-proof properties, crack prevention, anti-sagging, impact resistance, lightweight strength, and eco-friendly safety. Field applications have proven its superior performance over traditional options like paper-faced gypsum boards, magnesium oxide boards, and cement composite panels in protecting waterproof substrates against sanding, blistering, delamination, deterioration, and on-site damage.

3.TPO single roof waterproof node

The treatment of roof waterproof nodes combines the standard practice of national standard atlas and the construction design requirements of GAF. Meanwhile, the final node design scheme is confirmed on the basis of multiple on-site investigations, so that the project has a complete, reliable, durable and optimized roof waterproof system.

This project features numerous roof nodes and a tight schedule, requiring exceptional organizational skills and technical expertise from the waterproofing team. Beijing Guzhuo Construction Engineering Co., Ltd., the contractor, implemented an assembly-line management system for all trades based on project characteristics. The roof contains 130 skylight and exhaust window nodes, where TPO membrane installation demands highly skilled welding techniques. Manual torch welding would pose significant leakage risks, so automatic welding machines were deployed at the bottom of each skylight to prevent water leakage caused by human error.

3.1 Roof smoke exhaust window node

After completing the welding of the roof exhaust window frame and securing the inner panel, install the insulation board along the side of the skylight frame. Next, tightly adhere the membrane to the gypsum board, trim the edges inside the skylight base using a sealing strip, and apply sealant. At the bottom of the skylight, secure the membrane with U-shaped strips before covering it with the upper layer of membrane, which is then welded using an automatic welding machine.

Figure 4. Treatment of roof light window

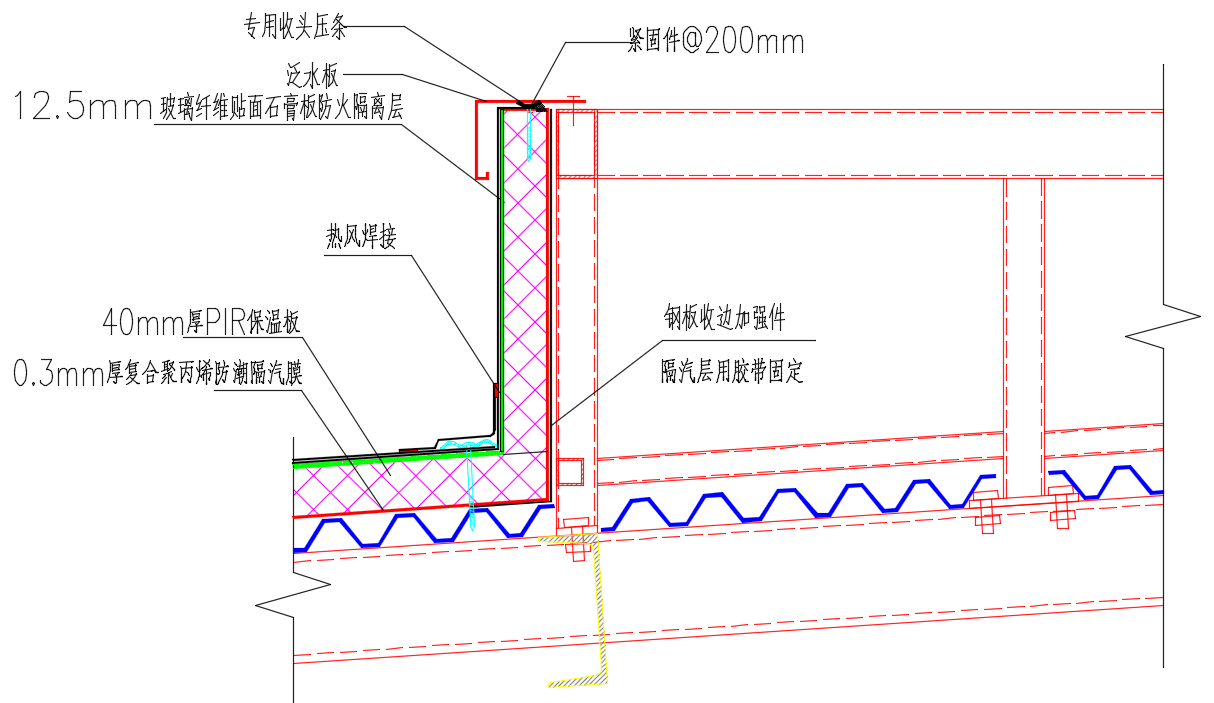

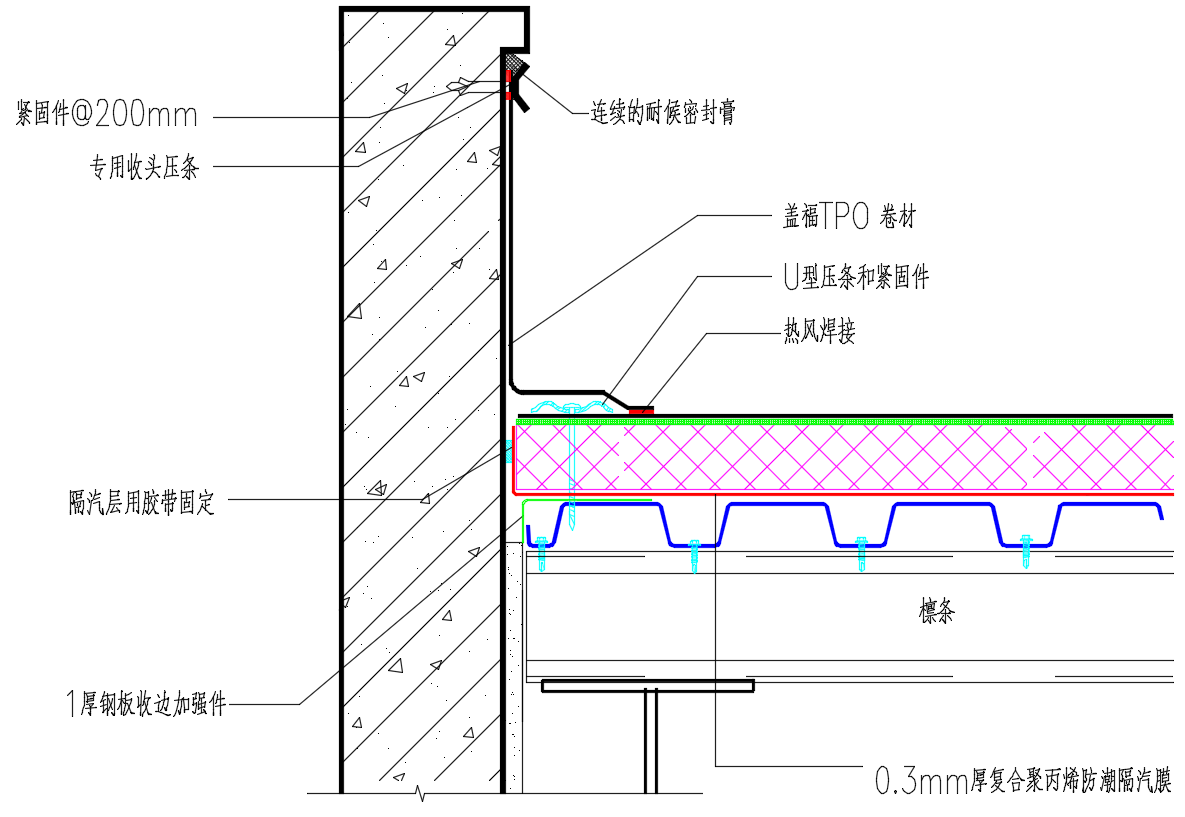

3.2 Treatment of gable nodes

The large-area membrane is installed at the base of the parapet wall, secured with U-shaped strips to resist wind pressure. The concrete gable wall facade is then treated with TPO membrane for waterproofing, followed by professional finishing strips to seal the edges outward. The sealing area is treated with weather-resistant sealant, ensuring comprehensive waterproof protection for the entire roof system. Finally, the base layer is welded to the large-area TPO membrane using a hot air welder.

Figure 5 Wall node processing

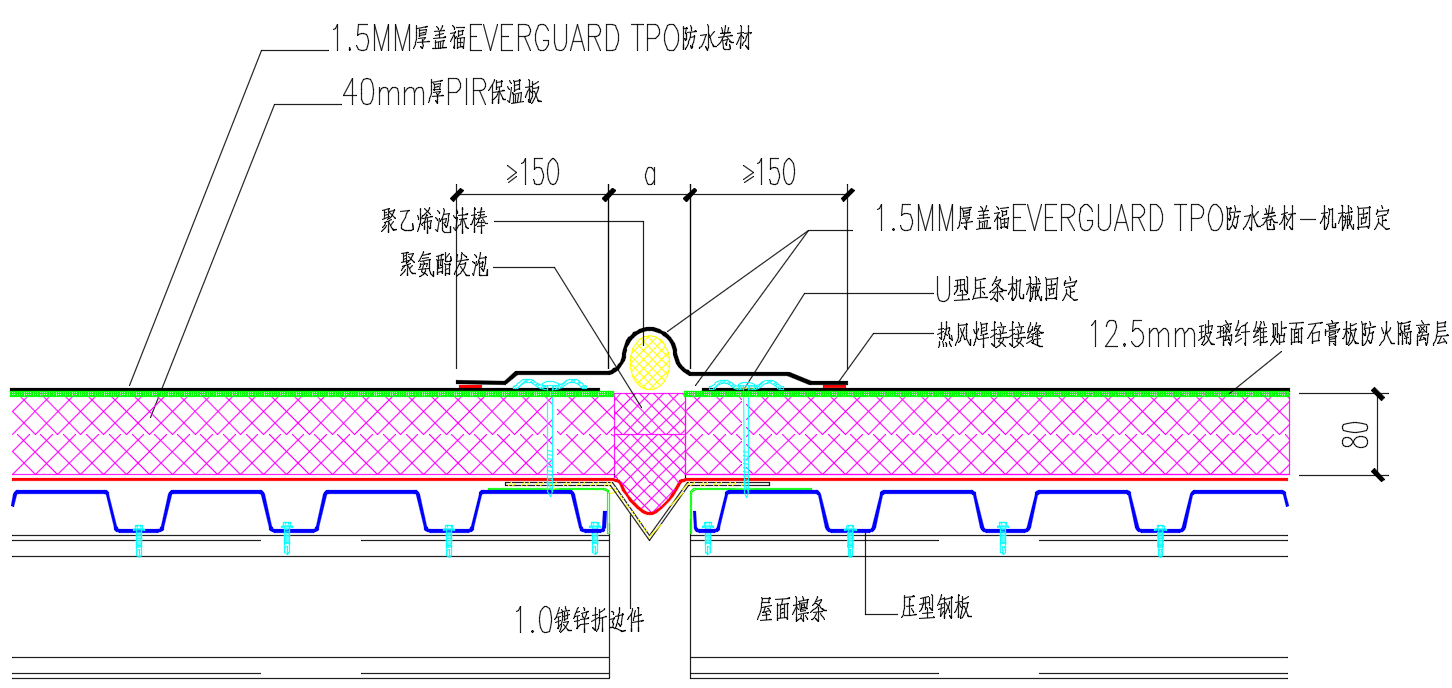

3.3 Treatment of deformation joint nodes

TPO membranes demonstrate exceptional elongation properties. For large-area membrane installations, deformation joints are first disconnected and secured. U-shaped compression strips are applied on both sides of the deformation joint plane, followed by separate welding to the exterior wall panels. A PE rod is then inserted at the center of the deformation joint, while a specially sized TPO membrane is installed to fully cover the joint area. Finally, the entire assembly is welded tightly to the parapet wall's waterproofing system using TPO material.

Figure 6. Treatment of joint in deformation seam

3.4 Treatment of external gutter nodes

The membrane covers the whole gutter part, and the special end sealing strip is pressed down on the wall top to hold the end, and the weatherproof sealant is sealed. The bottom of the gutter is fixed with U-shaped sealing strips on both sides to prevent the drainage from being affected by wind buoyancy.

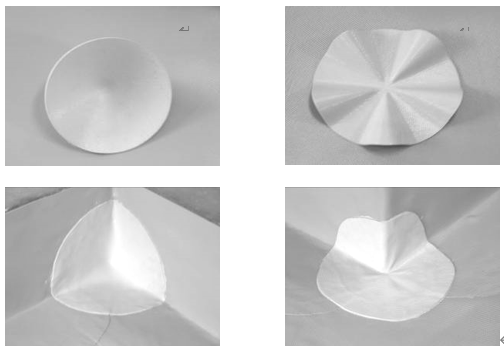

3.5 Treatment of Yin and Yang Angle nodes

The site uses self-made prefabricated yin and yang corners with special homogeneous TPO rolls for cover, as shown in the following figure: to ensure the complete and reliable waterproof effect of the node, improve the construction efficiency and increase the appearance.

Figure 7 Processing of Internal and external corner nodes

4. Conclusion

The project's roof utilizes the 30-year proven GAF TPO single-layer waterproofing system, offering mature construction techniques and comprehensive warranty services. The system employs mechanical fastening and hot-air welding technologies, delivering outstanding technical advantages and energy efficiency. Its durable materials ensure long service life with low maintenance costs. The innovative PIR insulation panels meet the high-temperature and high-humidity requirements for long-term condensation prevention in paper production workshops, while their recyclable and reusable properties support the achievement of carbon peaking and carbon neutrality goals.

Next Page

Related news