preferred building materials

DensDeck® Prime Roof Board

a special fire-resistant board that has fire resistance, thermal insulation, and recyclable properties, applied in various commercial roofing systems. The product featuresthat both its front and back are bonded with reinforced fiberglass...

category:

keyword:

Product Description

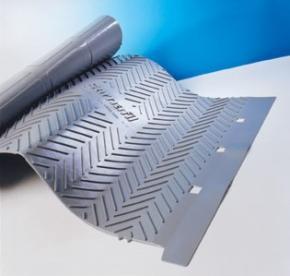

DensDeck® Prime roof panel is a special fire-resistant board with fireproof, thermal insulation, and recyclable properties, applied to various commercial roofing systems. The product features reinforced fiberglass layers bonded to both the front and back surfaces, with a gypsum core inside, providing excellent fire resistance and wind uplift resistance. The unique structure of DensDeck® Prime roof panel offers superior cross-sectional span (bottom plate opening width) for roof decks, enhancing the overall stability of the roof structure. Additionally, project applications have demonstrated that the special properties of DensDeck® Prime roof panel can more effectively protect the roof waterproof base layer from issues such as sanding, blistering, delamination, deterioration, and construction site damage compared to gypsum board, magnesium oxide board, and perlite insulation. Tested to ASTM D3273 standards, DensDeck® Prime roof panel has anti-microbial and anti-mildew properties.

Main Applications

Roof system manufacturers and designers have found DensDeck® Prime roof panels compatible with many types of roofing systems, including: modified bitumen, single-ply roofing, metal roofing systems, renovation/repaired roofs, and polyurea/polystyrene insulation. DensDeck® Prime roof panels can also be used as formwork for gypsum concrete bases in roof casting and as substrates for on-site foamed roofing systems. 1/2" (12.7 mm) and 5/8" (15.9 mm) DensDeck® Prime roof panels can also be applied as lining boards for gable facades or the top/sides of parapet walls. Cold mastic modified bitumen can be directly torch-bonded to this surface. DensDeck® Prime roof panel is an ideal base for vapor barriers.

Standards and Approval Codes

DensDeck® Prime roof panel complies with ASTM C1177 standards, with specific approval codes as follows:

- Florida Product Approval Code FL1250

- Miami-Dade County, Florida NOA08-0908.10

Recommendations and Limitations

DensDeck® Prime roof panels are designed for suitable roofing systems based on excellent roofing designs, with professional design departments responsible for determining their application in specific roofing systems or layers. Please consult professional system manufacturers or design departments for system and scheme design, as well as installation specifications and instructions for other products. Georgia-Pacific does not engage in the design or consulting of any products or systems. When using special adhesives or primers, allow sufficient time for full bonding to avoid damaging roof components. DensDeck® Prime roof panels should not bear abnormal or overload loads or foot traffic, such as large equipment with steel rollers, which may damage the panels. When hot asphalt application is required for roof panels, provide appropriate roof system protection as needed. Georgia-Pacific recommends that the application temperature for asphalt-based products should be between 425°F (218°C) and 450°F (232°C). Application temperatures exceeding this range may adversely affect roof system performance. For temperatures above 450°F (232°C) or wiping of Type IV asphalt, it is recommended to use strip or on-site scrubbing or install perforated base sheets instead of full mopping. Consult professional manufacturers for project-specific requirements on specifications, applications, and temperatures. When using DensDeck® Prime roof panels as a base for torch-on applications, ensure the product is dry and use appropriate construction methods to limit heat on the panel, keeping most of the torch flame directly on the roller. Conditions beyond Georgia-Pacific's control, such as weather, dew, leaks, application temperatures, and techniques, may adversely affect roofing systems.

Moisture Control

Like other components in roof systems, DensDeck® Prime roof panels must be protected from moisture before, during, and after installation. Remove plastic packaging immediately upon receipt; delayed removal may cause condensation or moisture penetration. If stored outdoors, stack panels horizontally on the ground, cover with waterproof breathable materials, and place in a ventilated area. DensDeck® Prime roof panels must be covered on the day of installation. Avoid using them in rain, fog, or other conditions that may wet the surface. In winter months, avoid excessive use of non-ventilated direct-fired heaters. When installing roof systems over new cast concrete or lightweight concrete bases or over damp existing concrete bases, install ventilated underlayment or vapor retarders above the concrete to prevent water migration into roof components. Always consult roof system manufacturers or design departments for detailed instructions on DensDeck® Prime roof panel products. Convective moisture flow must be eliminated, and leaks caused by roof defects must be controlled. After leaks, surface condensation on the roof system should be wiped clean immediately, and water inside the building must be drained as soon as possible. Although DensDeck® Prime roof panels are designed with fiberglass materials and high-density gypsum core, free moisture can harm product performance and roof membrane installation—for example, hot asphalt may blister, torch-applied asphalt may not bond properly, or single-ply membrane adhesives may not dry correctly. Moisture accumulation can also significantly reduce wind uplift values in systems or components. DensDeck® Prime roof panels with excessive free moisture content may require structural stability testing to ensure wind uplift values meet safety standards.

DensDeck® Prime roof panels have excellent fire separation performance on both combustible and non-combustible roof bases (including steel roof structures).

UL790 Classification

DensDeck® Prime roof panels are classified by Underwriters Laboratories (UL) under ANSI/UL 790 test standards as fire separation layers for combustible and non-combustible bases. UL classifications include comprehensive Class A, B, or C ratings. For more information on UL 790 classifications, refer to the UL certification directory.

UL1256 Classification

Tested per ANSI/UL 1256 Steiner Tunnel Test, DensDeck® Prime roof panels are also UL-listed for internal (below the base) fire exposure in roof base structures. For more information on UL1256 classifications, refer to the UL certification directory.

FM Class 1 Certification

DensDeck® Prime roof panels are included in many roof system modules with FM Class 1 fire ratings. The 1/4" (6.4mm) DensDeck® Prime roof panel has passed tests under FM Calorimeter 4450 standards and is approved by FM for installing insulated metal roof panels under FM-specified conditions. For more information on DensDeck® Prime roof panel FM certifications and Class 1 components, visit the FM website.

Type X Fire-resistant Board

The 5/8" (15.9mm) DensDeck® PrimeFireguard® roof panel is manufactured to meet the "Type X" requirements of ASTM C1177, enhancing fire resistance beyond gypsum board.

UL Fire Ratings

The 5/8" (15.9mm) DensDeck® PrimeFireguard® roof panel is designated as Type DD by UL and included in UL-researched hourly fire-resistant component designs. The 5/8" (15.9mm) DensDeck® PrimeFireguard® roof panel can also replace any unclassified 5/8" (15.9mm) gypsum board and can be added to any UL fire-resistant performance combination module under the prefix "p" in the directory.

Flame Spread and Smoke Test

According to ASTM E84 testing, DensDeck® Prime roof panels have a flame spread rating of 0 and a smoke density rating of 0.

Wind Loads

DensDeck® Prime roof panels are included in many components evaluated for wind load performance by FM or other independent laboratories. For information on these modular components, visit www.roofnav.com.

Previous Page

Next Page

Previous Page

Next Page

ONLINE MESSAGE

* Today there is a discount for leaving funds. Please make sure to fill in the information accurately and keep communication open. We will contact you as soon as possible