preferred building materials

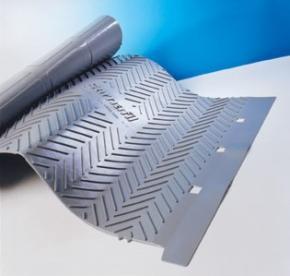

DOW Styrofoam® Polyurethane Pad

is one of the materials designated for use by the National Energy Conservation Center, with a compressive strength of 30Mpa and a thermal conductivity of ≤0.060W/( m·K) (-160℃ when)and a density of ≥480kg/m3...

category:

keyword:

Product Description

Polyurethane insulation pad is one of the materials designated for use by the National Energy Conservation Center, with a compressive strength of 30Mpa and a thermal conductivity of ≤0.060W/( m·K) (-160℃ when)and a density of ≥480kg/m3, with almost zero water absorption, relatively stable chemical and physical properties, and can function well within the design lifespan of cold storage, making it a very reliable system at this stage. The base insulation pads have several bolt holes, and the anchor bolts pass through the bolt holes of the base insulation pads to connect the steel columns and the lower raft.

Technical parameters of PU block

|

Item |

Value |

Testing Standard |

|

Density/( kg·m3) |

>=500 |

ASTM D5140 |

|

Compressive strength (2% deformation) /MPa |

7. 0 |

ASTM D1621 |

|

Compressive strength (10% deformation) /MPa |

30. 0 |

ASTM D1621 |

|

Thermal conductivity (20℃) /( W·m -1·K -1) |

0.075 |

ASTM C177

|

|

Thermal conductivity (-160℃)/( W·m -1·K -1) |

0. 051 |

ASTM C177

|

|

Coefficient of thermal expansion/K -1 |

58.7 ×10 -6 |

ASTM D696 |

|

Tensile strength/MPa |

6. 1 |

ASTM D1623 |

DOW STYROFOAM Brand Column-Bearing Blocks (500KG/M³) performance description in cold storage applications

1. Introduction

Dow Chemical, as a leading enterprise in the cold storage industry, has a history of 65 years. It is committed to providing high-performance, long-lasting energy-saving products for the low-temperature industrial construction industry. The STYROFOAM LT series column-bearing blocks have now officially joined this lineup. Like other products provided by Dow Chemical, the STYROFOAM column-bearing blocks meet the stringent requirements of designers and engineering companies for insulation in cold storage buildings. At the same time, the rich product series for cold storage maximizes convenience for customers to select solutions for their energy-saving needs.

Performance of STYROFOAM column-bearing blocks:

1) Highly energy-efficient. Solves the cold break problem of prefabricated cold storage steel column bases.

2) Stable high compressive strength. The physical properties with high pressure strength meet load-bearing requirements, ensuring structural safety.

3) Condensation prevention. The structure of the specially formulated closed-cell polyurethane prevents condensation, and its stable chemical properties will not react with the steel column base to cause corrosion.

4) Quick installation. Each STYROFOAM block is precisely cut in the factory according to the drawing requirements, with holes drilled according to the data of the site anchor bolts, ensuring seamless installation on site. On-site construction personnel do not need to perform any processing and can directly carry out assembly line installation.

Comprehensive insulation performance:

The STYROFOAM column-bearing blocks are made from a specially formulated high-density polyurethane composite material by Dow Chemical, forming an insulation thermal break between the steel column base and the concrete foundation. It has a special formulation and manufacturing process that provides high compressive strength, water resistance, condensation prevention, corrosion resistance, and non-solubility. After installation at the base of the column, the surface of the pad is compatible with the vertical column and will not corrode the steel structure, ensuring safety and reliability.

The STYROFOAM column-bearing blocks are available in two pressure specifications: 30 MPa and 50 MPa (according to ASTM D1621 compressive testing standards).

2. Testing methods for STYROFOAM column-bearing blocks

Compressive strength, thermal conductivity, tensile tests, and thermal expansion tests are conducted according to ASTM D1621, ASTM C177, ASTM D1623, and ASTM D696 standards.

3. Characteristics and effects of STYROFOAM column-bearing blocks (Dow STYROFOAM Brand Column-Bearing Blocks 500KG/M³)

1. Insulation performance

The thermal conductivity of STYROFOAM column-bearing blocks is low, providing good insulation effect (thermal conductivity at 20℃ is about 0.0750W/m·K; at -160℃, it is about 0.0502W/m·K).

2. Compressive performance and creep under long-term load

The compressive strength of STYROFOAM column-bearing blocks is very high (approximately 32.39MPa in the parallel upward direction and approximately 29.44MPa in the vertical upward direction), and its creep under long-term load is minimal, sufficient to bear the pressure of the overall steel structure on the column base for a long time, eliminating the possibility of reduced insulation performance and damage due to compression, deformation, or breakage of the insulation material.

3. Water and moisture resistance

The STYROFOAM column-bearing blocks have a tightly closed-cell honeycomb structure, and their chemical properties are very stable, resulting in excellent water resistance, with a water absorption rate of <1% (V/V). Even when fully submerged in water, their compressive performance remains almost unchanged.

4. Tensile performance

The tensile performance of STYROFOAM column-bearing blocks is good, with a fracture strength of approximately 5.079MPa in the parallel upward direction and a fracture elongation rate of approximately 10.86%; in the vertical upward direction, the fracture strength is approximately 6.079MPa, with a fracture elongation rate of approximately 10.3%.

5. Coefficient of thermal expansion

The thermal expansion coefficient of the "Shutailong" base pad is very low, with a thermal expansion coefficient of approximately 59.04×10 -6 K -1 parallel to the rising direction, and approximately 58.35×10 -6 K -1 in the vertical rising direction.

4. Pressure calculation of the cold storage base

1. Load values

1) Dead load: 0.3kPa

2) Live load: cold storage roof 0.7kPa (0.3 live load + 0.4 suspended load)

3) Basic wind pressure 0.55kN/m2, ground roughness is Class A

4) Basic snow pressure 0.2kN/m2

2. Seismic design

The seismic intensity is 7 degrees, and the design seismic group is the first group. The design basic seismic acceleration value is 0.1g, and the building site category is Class IV.

3. Vertical force values for the base

Upper load (maximum value of 560kN) + truss self-weight (20kN) + influence of adjacent shelf stacking load (approximately 500kN) ≈ 1100kN

Base plate size 0.8m×0.8m

The total pressure on the base plate is 1.75MPa

According to polyurethane design specifications, the design strength is set at 1/3 of the ultimate strength, so the design pressure for polyurethane should be greater than 5.25MPa.

According to our testing, the "Shutailong" base pad deforms by 2% at 7MPa, which is more than sufficient to meet the design requirements for such cold storage projects.

Previous Page

Next Page

Previous Page

Next Page

ONLINE MESSAGE

* Today there is a discount for leaving funds. Please make sure to fill in the information accurately and keep communication open. We will contact you as soon as possible