preferred building materials

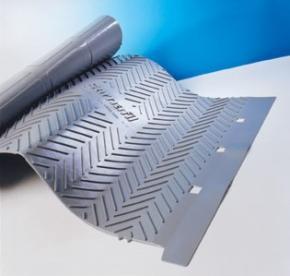

DOW Spray Foam Polyurethane

is formed by mixing isocyanate (commonly known as black material) and blended polyol (commonly known as white material) under high pressure, expanding about 30 times in volume and curing within seconds...

category:

keyword:

Product Description

Polyurethane spray foam is formed by mixing isocyanate (commonly known as black material) and blended polyol (commonly known as white material) under high pressure, expanding about 30 times in volume and curing within seconds. Depending on different applications, polyurethane spray foam can be formulated to achieve different physical and flame-retardant properties, possessing excellent physical properties, weather resistance, and solvent resistance. Polyurethane spray foam has outstanding long-term thermal insulation performance and can be widely used for insulation in external walls, roofs, storage tanks, ships, pipelines, etc.

White material: Blended polyether polyol Polyol

• Polyether polyol

• Surfactant

• Catalyst

• Chemical blowing agent

• Physical blowing agent

• Flame retardant

Black material: Isocyanates

• A series of organic compounds containing (-NCO)

• An important component affecting the physical properties of foam

Polyurethane rigid spray foam – Physical performance indicators

Test items | Roof Type I | Roof Type II | Roof Type III | Wall Type I | Test method |

Density (kg/m3) | ≥35 | ≥45 | ≥55 | ≥35 | GB6343 |

Thermal conductivity [W(m∙K)] | ≤0.024 | ≤0.024 | ≤0.024 | ≤0.024 | GB3399 |

Compressive strength 10% (Mpa) | ≥0.15 | ≥0.200 | ≥0.30 | ≥0.15 | GB/T 8813 |

Dimensional stability (70oC, 48Hr)(%) | ≤1.5 | ≤1.5 | ≤1.0 | ≤1.5 | GB/T 8811 |

Bonding strength (MPa) | - | - | - | ≥0.10 | Appendix B |

Closed cell content (%) | ≥90 | ≥92 | ≥95 | ≥90 | GB/T10799 |

Water absorption (%) | ≤ 3 | ≤ 2 | ≤ 1 | ≤ 3 | GB 8810 |

Dow polyurethane rigid spray foam typical products

Spray polyurethane physical properties | Roof spraying | Wall spraying | |

Class II | Class III | Class I | |

Dow typical products | Voracor* CY 3225 polyol/Voracor* CY 3211 polyol | Voracor* CY 3162 polyol/Voracor* CY 3226 polyol | Voracor* CY 3217 polyol/Voracor* CY 3218 polyol |

Density (Kg/m3) | ≥ 45 | ≥ 55 | ≥ 35 |

Thermal conductivity (W/m·K) | ≤0.024 | ≤0.024 | ≤0.024 |

Compressive strength (KPa) | ≥ 200 | ≥ 300 | ≥ 150 |

Closed cell content (%) | ≥ 92 | ≥ 95 | ≥ 90 |

Adhesive strength (to cement substrate) | ≥ 100 kPa | ≥ 100 kPa | ≥ 150 kPa |

Water resistance (1000mm water column, 24 hours) | ≤ 5mm | ≤ 5mm | ≤ 5mm |

Dimensional stability (70℃, 48 hours, %) | ≤ 1.5% | ≤ 1% | ≤ 1.5% |

Water vapor permeability (ng/Pa.m.s) | ≤ 5 | ≤ 5 | 1.5~4.5 |

Combustion performance | B1/B2 | B2 | B2 |

Water absorption (%) | ≤2 | ≤1 | ≤3 |

Previous Page

Previous Page

Next Page

ONLINE MESSAGE

* Today there is a discount for leaving funds. Please make sure to fill in the information accurately and keep communication open. We will contact you as soon as possible