preferred building materials

Pulen International Jingbin Cold Storage

category:

keyword:

Product Description

1. Project Location Advantage:

This project is located in the Jingbin Industrial Park of Wuqing District, Tianjin, situated in the core area of the "Golden Triangle" of Beijing-Tianjin-Hebei. It serves as an important link connecting the two major cities of Beijing and Tianjin, with a direct border to Langfang in Hebei to the west and Beijing to the north. The location advantage is obvious, and transportation is very convenient.

2. Project Scale:

The completed and operational cold storage units 1#, 2#, and 3# are low-temperature sorting workshops and supporting cold storage facilities. The width of the return yard is 30 meters, meeting the needs for large refrigerated trucks to park.

Cold storage units 1# and 2# are single-layer insulated prefabricated steel structure cold storages, covering an area of approximately 6000 square meters, with the cold room occupying about 5000 square meters. The net height inside the warehouse is 10.5 meters, and the column spacing is 8*20. The shelving form adopts 5-layer double-deep shelves, with pallet dimensions of 1.2 * 1.0. The uniformly distributed load inside the warehouse is designed for 5 tons. In addition to double-deep shelves, shuttle rack systems can also be used. The total number of pallet positions for double-deep shelves is approximately 15600; the total number of pallet positions for shuttle racks is approximately 25000.

Cold storage unit 3# is a three-layer civil construction cold storage. The net height of the first layer is 9 meters, and the column spacing is 7.8*7.6. Double-deep shelving can be used, with a 4-layer shelf layout, and the total number of pallet positions on the first layer is approximately 4524. The net height of the second and third layers is 4.5 meters, and goods are stored in a scattered pile format, suitable for storage-type and reserve-type low-temperature goods, with a total number of pallet positions of approximately 6490. The cold storage has two 5T freight elevators set up for vertical transportation of goods between the second and third layers.

3. Project Construction Standards:

The refrigerant used in this project is environmentally friendly refrigerant 507. The compressor uses imported front-mounted screw units, and the cold air units use full liquid cold air units. All refrigeration valve components are selected from Danfoss valves. The refrigeration system uses PLC automatic control, which can automatically adjust the working status of the compressor, condenser, cold air units, and refrigeration valve components according to the set warehouse temperature, allowing the entire refrigeration system to operate at a high energy efficiency ratio.

The insulation boards for cold storage units 1# and 2# use 200mm thick B1 grade PIR insulated sandwich panels, and the ground insulation uses Beipeng extruded polystyrene boards (500kpa). The insulation inside cold storage unit 3# is 200mm thick B1 grade spray insulation. At the same time, the outer cladding panels of cold storage units 1# and 2# are 5cm thick rock wool sandwich panels, further enhancing the insulation performance of units 1# and 2#. The calculated energy consumption does not exceed 0.5 kWh/day.

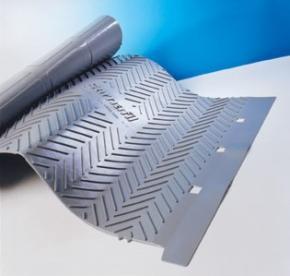

The steel structure roof of cold storage units 1# and 2#, and the civil construction roof of unit 3# adopt a "Sika PVC + rock wool insulation layer + vapor barrier" single-layer roof waterproof system, effectively ensuring the stability and reliability of the roof waterproof system throughout the life cycle of the cold storage. The flooring uses a 4mm Sika Sikafloor 24N PurCem polyurethane mortar flooring system specifically for cold storage, ensuring the integrity, reliability, and safety of the cold storage flooring under -25℃ low-temperature conditions. The roofing and flooring systems of this project meet international high-quality standards, with design and construction completed by Beijing Guizhuo Construction Engineering Co., Ltd., providing strong assurance for the successful operation of the project.

The uniformly distributed load inside all cold storages is designed for 5 tons, accommodating both double-deep shelves and shuttle rack systems, fully considering the diversity of operations in the later stages.

The exterior of the cold storage has sockets for refrigerated trucks, and the return yard is equipped with charging stations for refrigerated trucks.

Previous Page

Next Page

Previous Page

Next Page

ONLINE MESSAGE

* Today there is a discount for leaving funds. Please make sure to fill in the information accurately and keep communication open. We will contact you as soon as possible